Test methods:

2. Setting test cycles of needed abrupt pull in the touch screen, for example, 200 cycles. When reaching set test cycles, it will stop testing automatically.

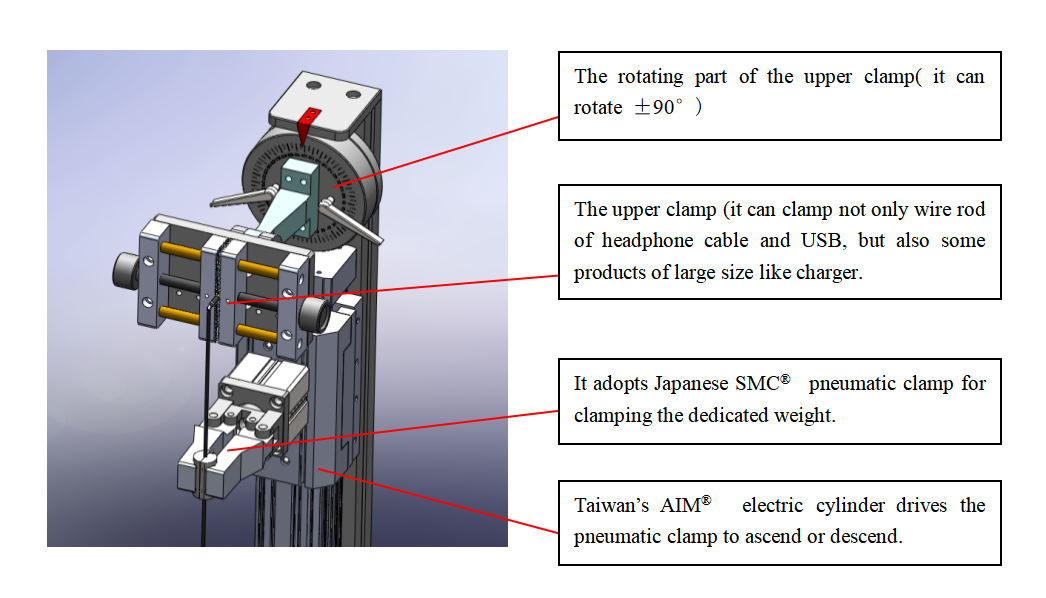

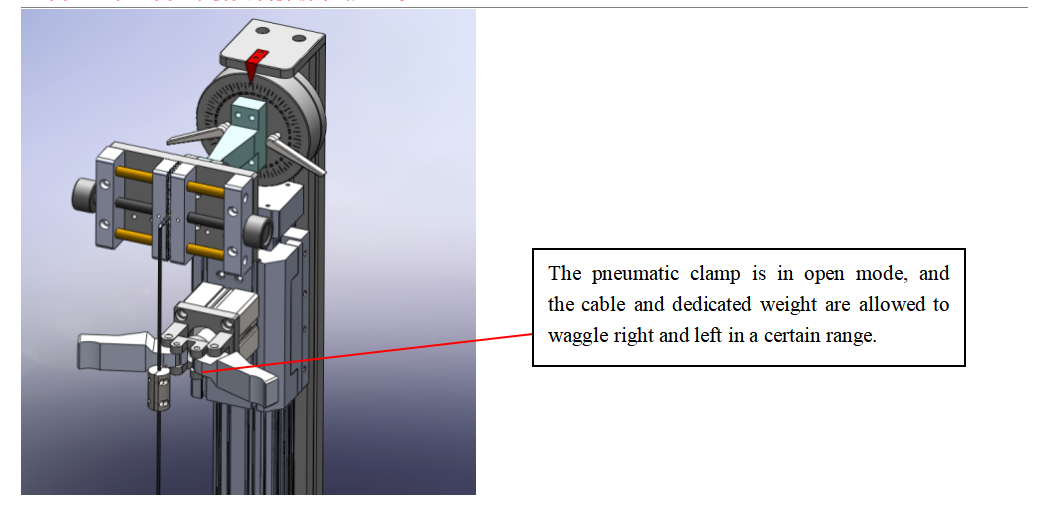

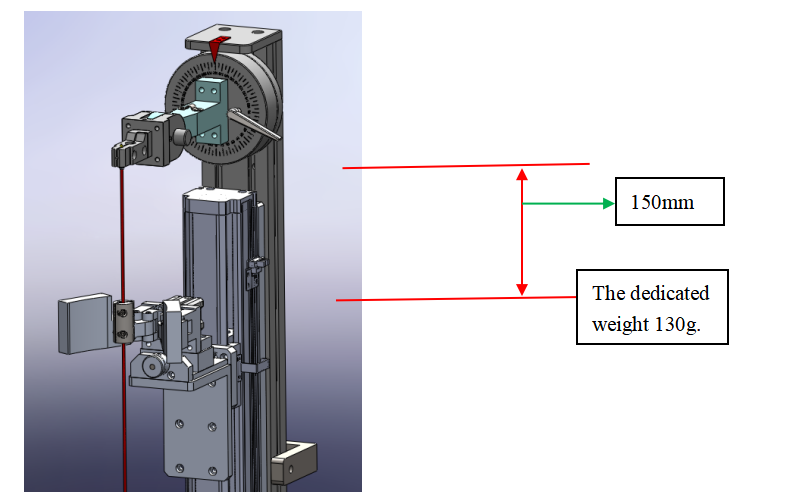

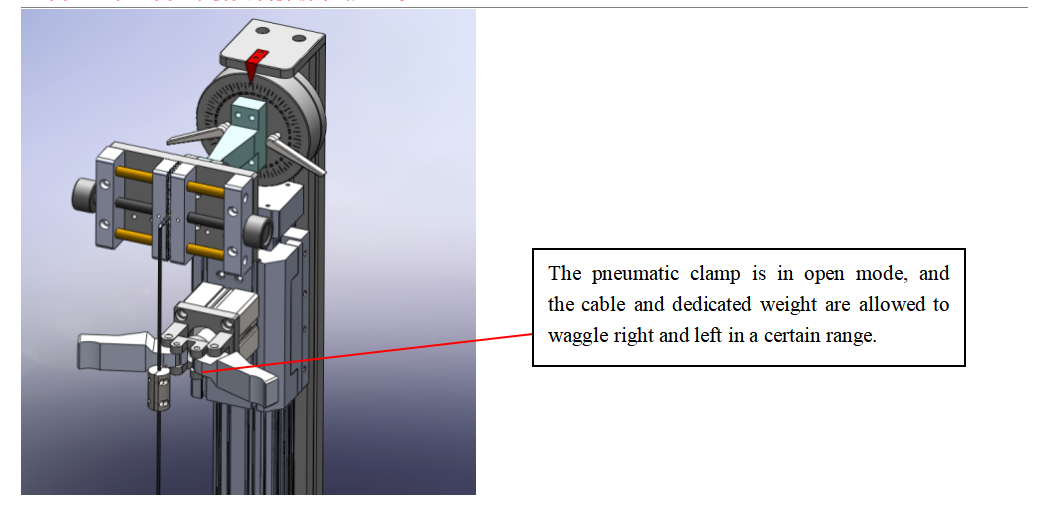

3. Pressing test key; pneumatic fixture clamps the dedicated weight; electric cylinder drives the weight to rise 150mm; pneumatic clamp immediately loosens; abrupt drop of weight leads to abrupt pull test on cable; pneumatic fixture clamps dedicated weight; electric cylinder drives dedicated weight to rise the cycle repeats until it finishes set test cycles.

4. The main unit is designed with optoelectronic switch, so if the cable is snapped in the test and resulting in weight dropping to the baseboard, the machine will automatically stop testing with audible and visible alarm.

Features:

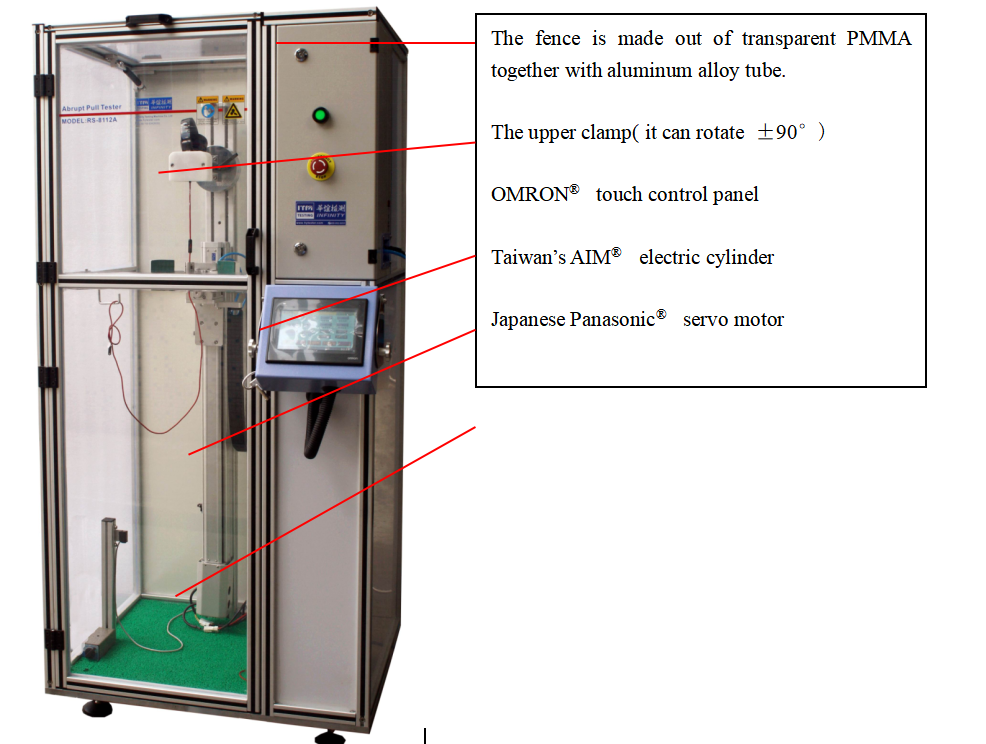

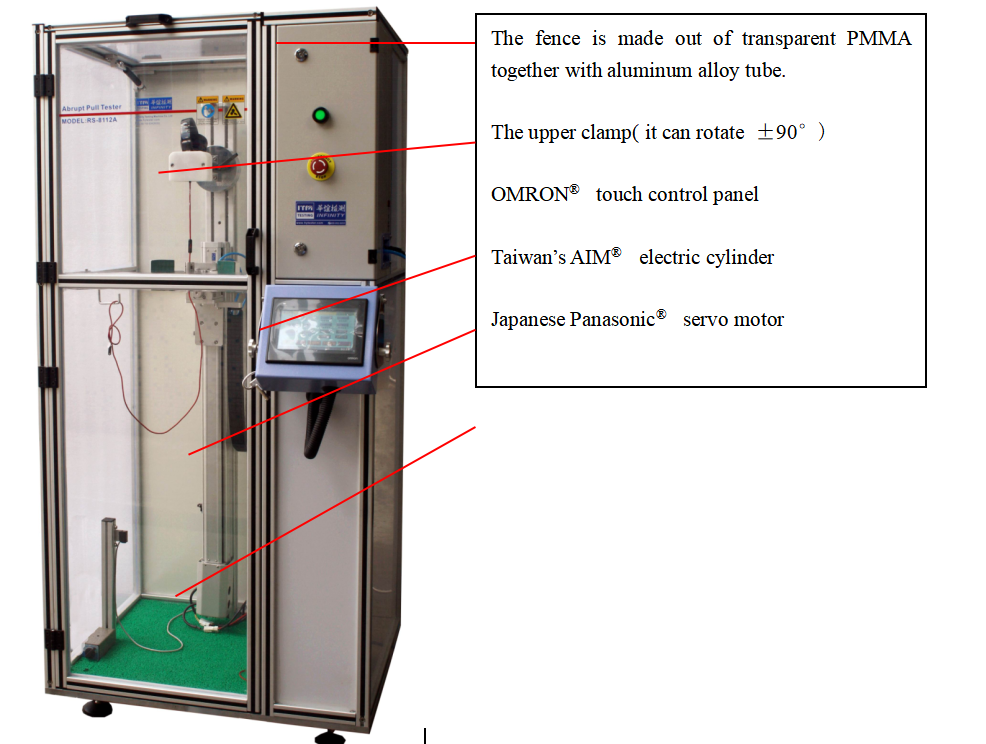

Equipment appearance diagram:

Bill of main materials:

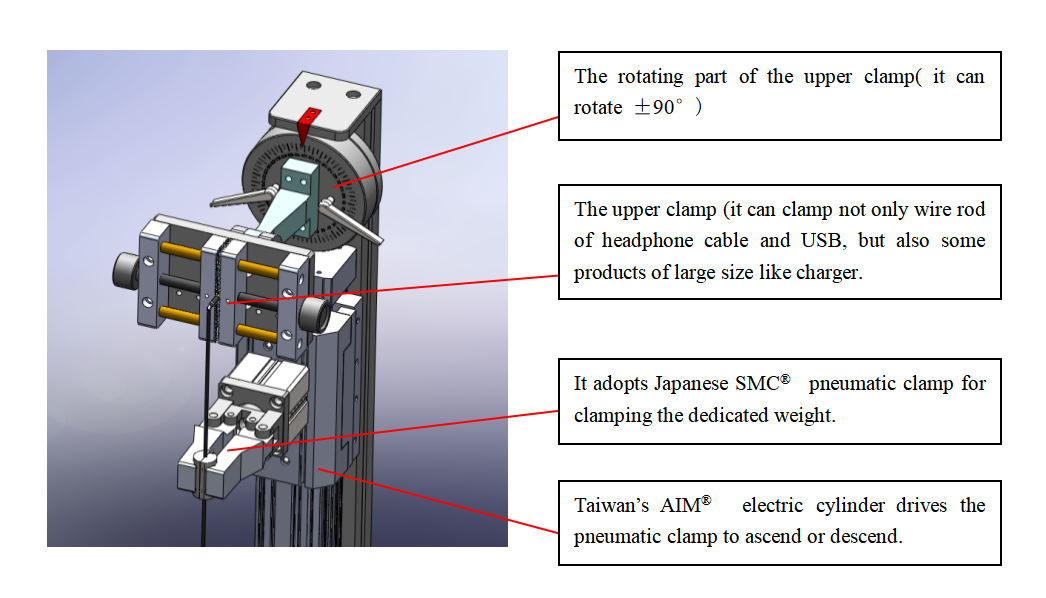

- Fastening one end of the power wire or headphone to the clamp, as is shown in the picture below (the plug is clamped vertically or transversely. Fastening the dedicated weight to the cable on the position 150mm away from the plug, the clamping weight is 130g.

2. Setting test cycles of needed abrupt pull in the touch screen, for example, 200 cycles. When reaching set test cycles, it will stop testing automatically.

3. Pressing test key; pneumatic fixture clamps the dedicated weight; electric cylinder drives the weight to rise 150mm; pneumatic clamp immediately loosens; abrupt drop of weight leads to abrupt pull test on cable; pneumatic fixture clamps dedicated weight; electric cylinder drives dedicated weight to rise the cycle repeats until it finishes set test cycles.

4. The main unit is designed with optoelectronic switch, so if the cable is snapped in the test and resulting in weight dropping to the baseboard, the machine will automatically stop testing with audible and visible alarm.

Features:

- It adopts Japanese OMRON® touch screen and Mitsubishi® PLC for control, you can set specifications including test cycles, resetting original height, ascending and descending speed of pneumatic cylinder and clamp delay, etc. it can display finished test cycles and other information so as to achieve automatic test.

- It adopts Japanese Panasonic® AC servo drive and Taiwan’s AIM® electric cylinder drive. It has advantage of resetting precision ±0.02mm, low noise and being durable.

- The rail is combined international standard aluminum alloy with transparent PMMA, which enhances safety of the equipment.

- It adopts Japanese SMC® pneumatic clamp for clamping the dedicated weight

| Test station | 1Slot |

| Dedicated weight for abrupt pull | 130g±2g |

| Stroke of abrupt pull | 0~300mm (adjustable) commonly 150mm |

| Test cycles | 0~999999 cycles adjustable |

| Ascending and descending speed of electric cylinder | 1~500mm/sec |

| Positional accuracy of electric cylinder | ±0.02mm |

| Clamping delay | 1~99.9sec adjustable |

| Dimension | W750×D650×H1300mm |

| Weight | 95kg |

| Power | 1∮,AC220V,3A |

| Air source | ≥0.6MPa |

Equipment appearance diagram:

Bill of main materials:

| Component names | Qty | Purpose | Manufacturer |

| servo motor and actuator | 1 pcs | Lifting actuating and controlling | Japanese PANASONIC |

| Electric Actuators | 1 pcs | Lifting actuating drive | AIM Taiwan |

| Touch Panel Controller | 1pcs | Program setting | Omron Japan |

| Programmable logic controller | 1pcs | Edit test program | Japanese Mitsubishi |

| Test fixtuer | 1set | After the sample is clamped, the test is carried out | Infinity machine Inc. |

| Failure detection safety switch | 1set | During the test, when the wire is pulled off, the switch to detect the samples of FAIL will be given to stop the test signal | OMRON Japan |

| Box and sheet metal | 1set | Infinity machine Inc. |

.jpg)