Purpose:

This equipment is designed for testing the friction coefficient of glass, plastic film, paper, metal and other products. The purpose is to drive the sample to one side of the platform through the transmission mechanism, apply a slider to the surface of the sample, and then measure the static friction coefficient and dynamic friction coefficient of the sample and the slider through the force measurement system to obtain the friction coefficient of different batches of products. By measuring the smoothness of the material, the production quality process index can be controlled and adjusted to meet the requirements of product use.

Reference test standard:

ASTM D1894-06 Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting. GB 10006、ISO 8295

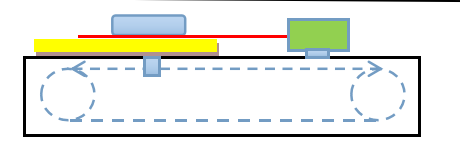

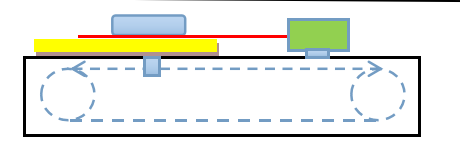

The test method is: Place the product on a smooth flat plate → place a slider on the product → Connect one end of the slider to the force sensor through a cable (nylon mono-fiber (dimension) wire) → During the test, the servo motor drives the product to one side at a speed of 150mm/min or 500mm/min for 130mm→ The force sensor records the entire friction of the product → computer software Automatically draw the curve and calculate the static friction coefficient and dynamic friction coefficient in the process → store the test results or output the test report. The schematic diagram is as follows:

Calculation formula of friction coefficient:

Calculation of static friction coefficient μs=As/B

Note: As= Reading of primary movement, (gram)

B= Weight of sliding pulley, (gram)

Calculation of dynamic n coefficient μk=Ak/B

Note: Ak= Average value as the material surface is reached and the constant motion is made

B= Weight of sliding pulley, (gram)

When the arithmetic average value is to be calculated, the three-time observations with the same standard shall be made.

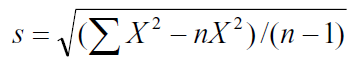

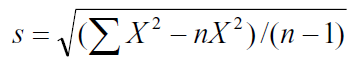

The calculation of standard deviation (estimated in accordance with the ±15% of normal friction coefficient) is as follows, and the two reports with valid estimations shall be formulated:

Note: S= Sample standard deviation

X= Observed value of individual part

n= Labels of observation

X= Standard deviation calculated by values of observing device (estimated in accordance with the ±15% of normal friction coefficient) is as follows, and the two reports with valid estimations shall be formulated:

The report shall contain the following information:

1.The sample descriptions of plastics shall be formulated, including the charge codes of Manufacturer, thickness, production methods, surface test and main testing direction together with approximate lifetime of production manufacturing.

2.If the second material is used, please state it.

3.Use of device

4.Average value of dynamic friction coefficient and static friction coefficient, and the standard deviation

5.Measuring quantity for friction coefficient of each kind of sample

6.Temperature of panel at the beginning of test

Software interface of friction coefficient test:

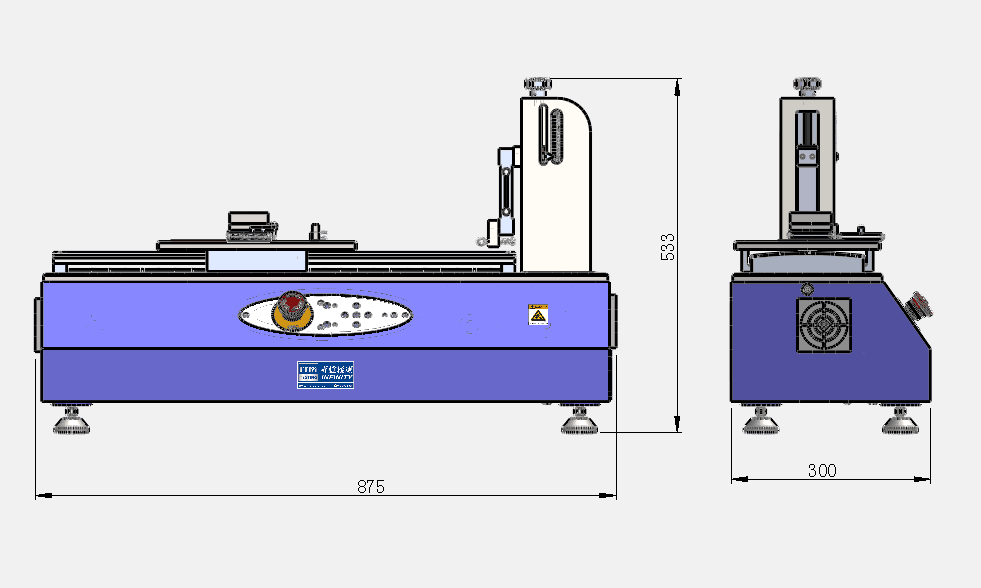

Technical parameters (delivery should be subject to physical!)

This equipment is designed for testing the friction coefficient of glass, plastic film, paper, metal and other products. The purpose is to drive the sample to one side of the platform through the transmission mechanism, apply a slider to the surface of the sample, and then measure the static friction coefficient and dynamic friction coefficient of the sample and the slider through the force measurement system to obtain the friction coefficient of different batches of products. By measuring the smoothness of the material, the production quality process index can be controlled and adjusted to meet the requirements of product use.

Reference test standard:

ASTM D1894-06 Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting. GB 10006、ISO 8295

The test method is: Place the product on a smooth flat plate → place a slider on the product → Connect one end of the slider to the force sensor through a cable (nylon mono-fiber (dimension) wire) → During the test, the servo motor drives the product to one side at a speed of 150mm/min or 500mm/min for 130mm→ The force sensor records the entire friction of the product → computer software Automatically draw the curve and calculate the static friction coefficient and dynamic friction coefficient in the process → store the test results or output the test report. The schematic diagram is as follows:

Calculation formula of friction coefficient:

Calculation of static friction coefficient μs=As/B

Note: As= Reading of primary movement, (gram)

B= Weight of sliding pulley, (gram)

Calculation of dynamic n coefficient μk=Ak/B

Note: Ak= Average value as the material surface is reached and the constant motion is made

B= Weight of sliding pulley, (gram)

When the arithmetic average value is to be calculated, the three-time observations with the same standard shall be made.

The calculation of standard deviation (estimated in accordance with the ±15% of normal friction coefficient) is as follows, and the two reports with valid estimations shall be formulated:

Note: S= Sample standard deviation

X= Observed value of individual part

n= Labels of observation

X= Standard deviation calculated by values of observing device (estimated in accordance with the ±15% of normal friction coefficient) is as follows, and the two reports with valid estimations shall be formulated:

The report shall contain the following information:

1.The sample descriptions of plastics shall be formulated, including the charge codes of Manufacturer, thickness, production methods, surface test and main testing direction together with approximate lifetime of production manufacturing.

2.If the second material is used, please state it.

3.Use of device

4.Average value of dynamic friction coefficient and static friction coefficient, and the standard deviation

5.Measuring quantity for friction coefficient of each kind of sample

6.Temperature of panel at the beginning of test

Software interface of friction coefficient test:

Technical parameters (delivery should be subject to physical!)

| Capacity | 5kgf(50N) |

| Unit of force value | N,kgf,Lbf |

| Resolution ratio | 1/500,000 |

| Accuracy of force value | ±0.5% |

| Resolution ratio of movement | 0.001mm |

| Accuracy of movement | ±0.5% |

| Test stroke | 0~400mm |

| Speed range of test | 0.01~1000mm/min |

| weight | 80*80mm section 200g/500g±2g standard weights (replaceable media, can be specified) 10*10mm sectional weight 5g/10g/20g |

| Sliding block | W10*D10*H15mm, and the weight is about 100g. W80*D80*H12mm, and the weight is about 500g. |

| Drive | AC servo motor |

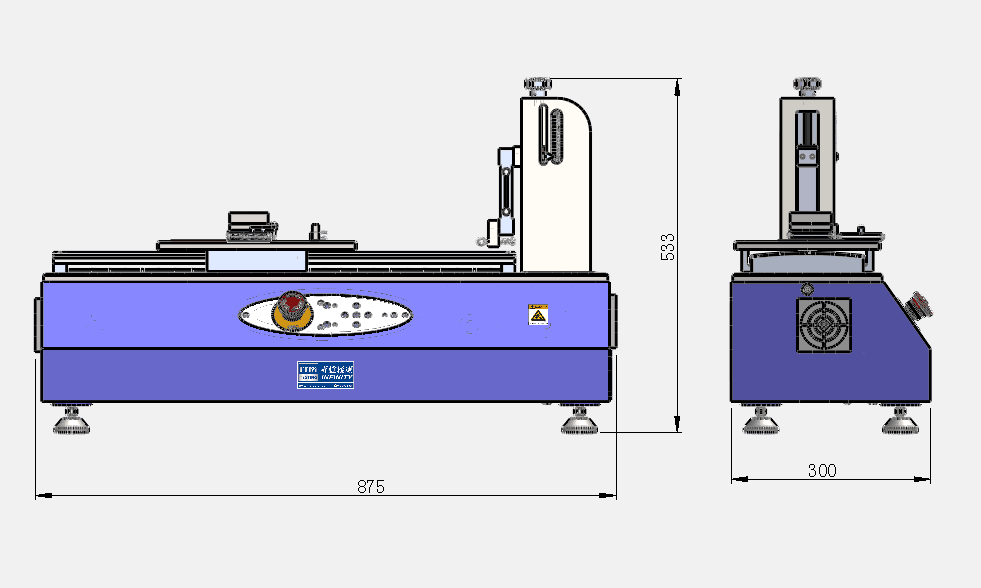

| Size of machine | About W870 x D300 x H540mm |

| Weight of machine | About 55kg |

| Power supply | 1∮AC220V 3A or the specified value |