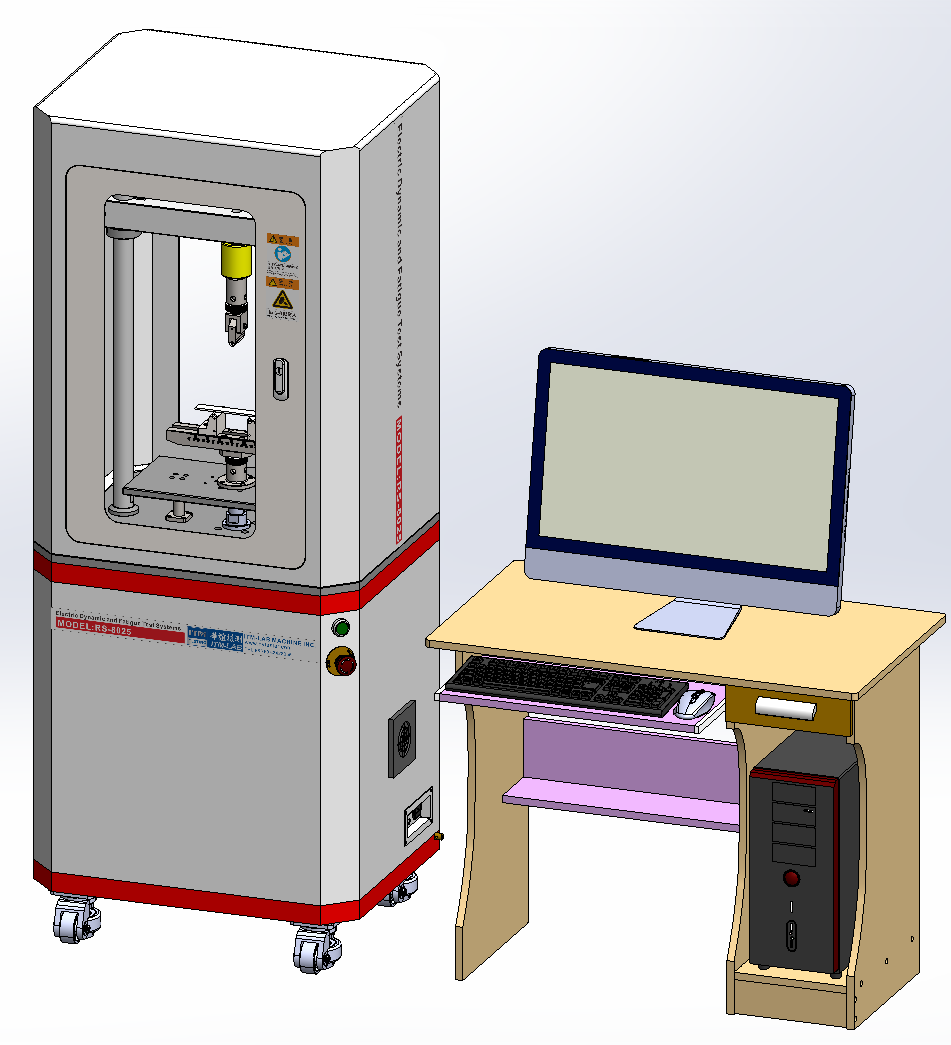

Electronic dynamic Tester MODEL:RS-8025 Series

Equipment Introduction:

The dynamic fatigue testing machine is primarily used for testing the dynamic and static mechanical properties of various metallic materials, non-metallic materials, components, elastomers, rubber elasticity and dampers, composite materials, and lithium battery core poles. It can perform tensile, compression, bending, low-cycle and high-cycle fatigue, crack propagation, and fracture mechanics tests under sine wave, triangle wave, square wave, trapezoidal wave, ramp wave, sawtooth wave, and user-defined conditions.

The testing machine is easy to operate and flexible, utilizing AC servo motor drive technology for loading, high-precision load sensors, and high-resolution displacement sensors to measure the force and displacement of the specimen. It meets the requirements for dynamic fatigue testing of materials as well as static tensile and compressive tests.

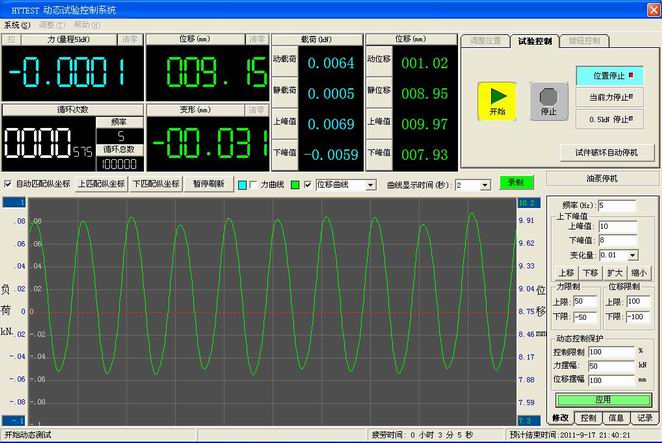

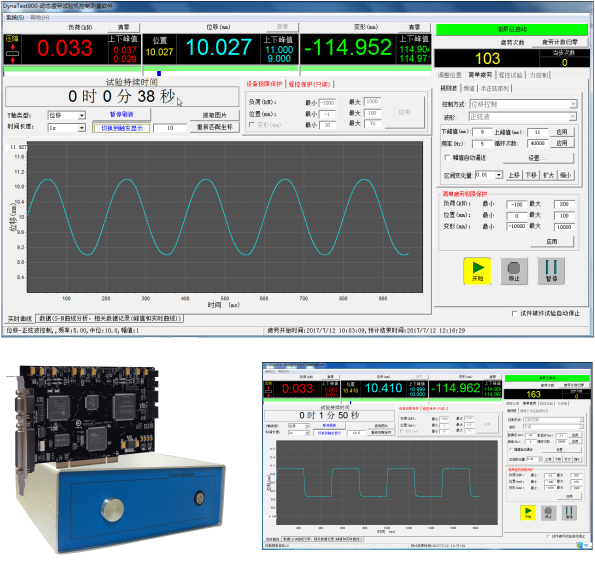

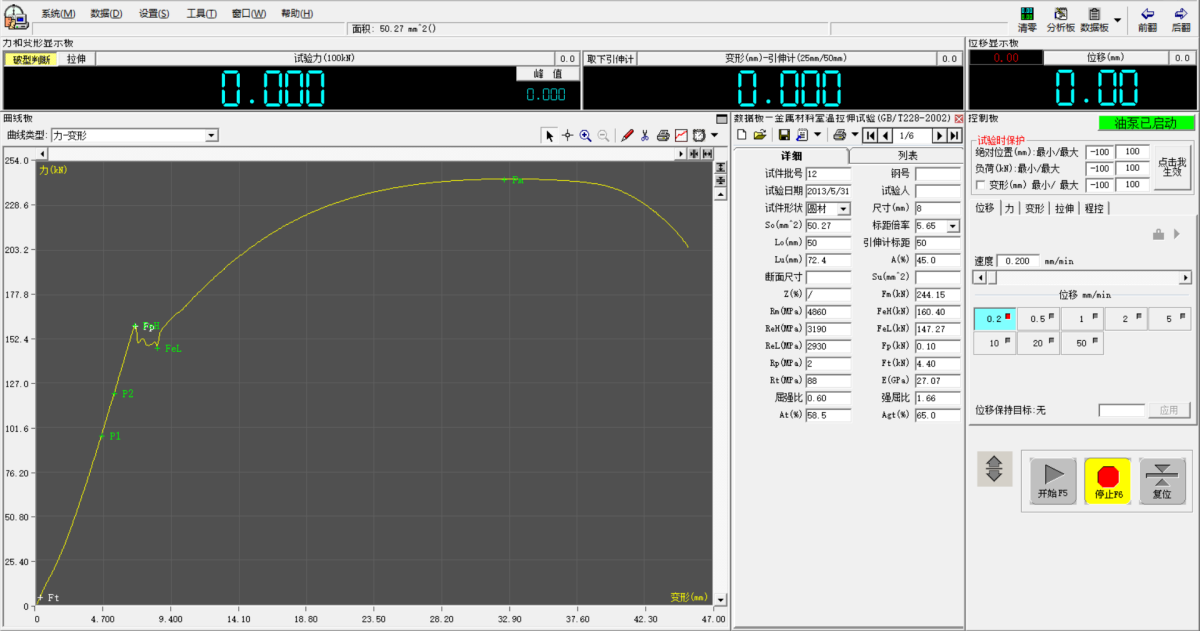

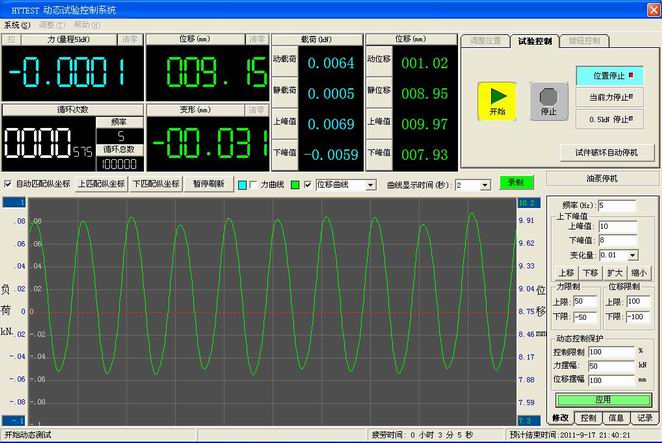

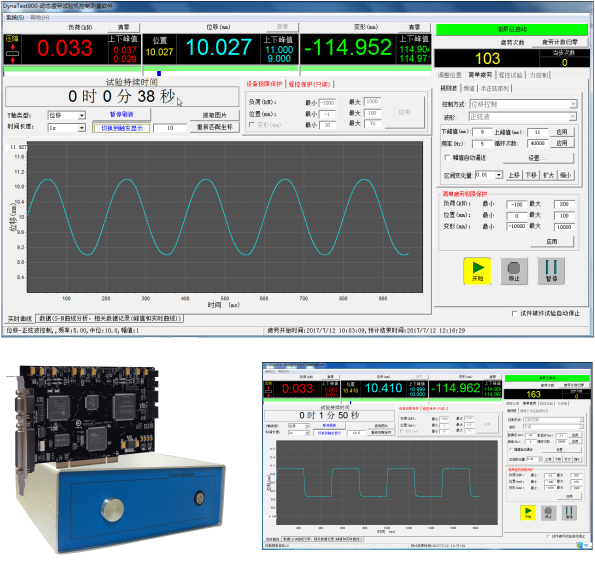

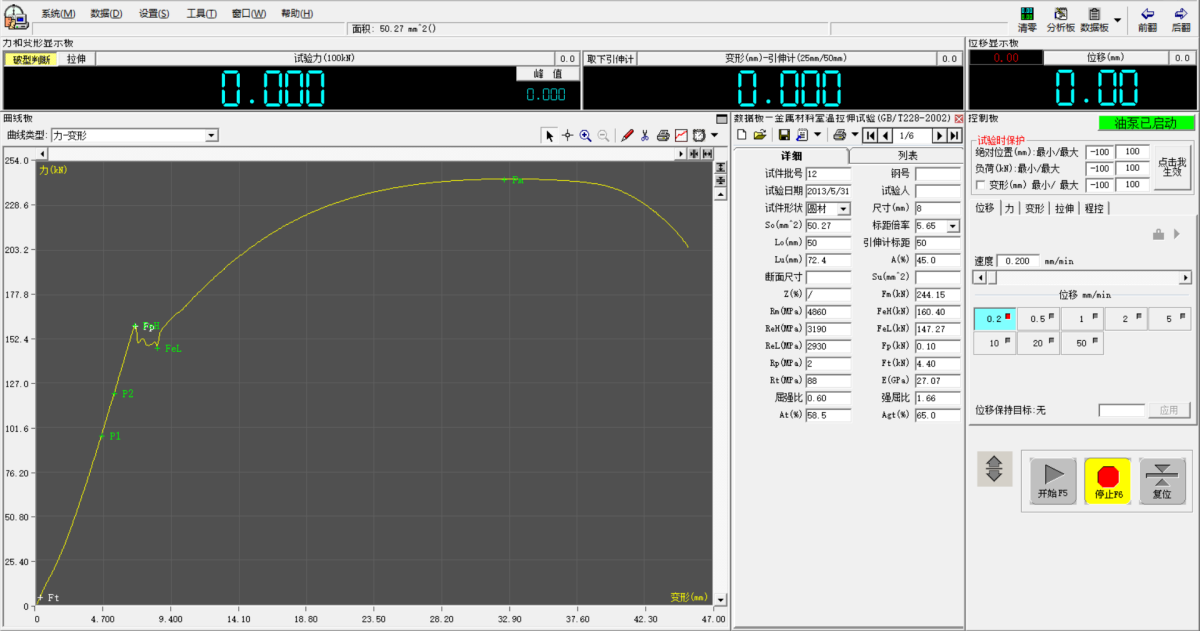

The fully digital measurement and control system can achieve force, dynamic displacement, and deformation cycle control. During the testing process, it displays the test's force value, displacement value, dynamic load value, static load value, and the upper and lower peak values, frequency, cycle count, and test duration in a non-file digital format, while simultaneously tracking and displaying the force and displacement curves in real-time; it also allows for real-time display and capture of dynamic data and waveforms. Flexible data storage method, during the test, automatically save test data in real-time based on the number of cycles or test time, ensuring the safety of test data.

According to standards:

Complies with GB/T2611 'General Technical Requirements for Testing Machines', 'Electronic Universal Testing Machines' GB/T 16491-2008, 'General Technical Requirements for Testing Machines' GB2611-2007, 'Detection of Force Measurement Systems for Tensile and Compression Testing Machines', 'Technical Conditions for Extensometers' JB6146-2007, and 'General Specifications for the Licensing Assessment of Manufacturing Measuring Instruments' JJF1246-2010. GB/T3075 'Metal Axial Fatigue Test Methods', JB/T9379 'Technical Conditions for Tensile and Compression Fatigue Testing Machines', GB/T228 'Room Temperature Tensile Test Methods for Metallic Materials', and other standard requirements.

Performance Characteristics:

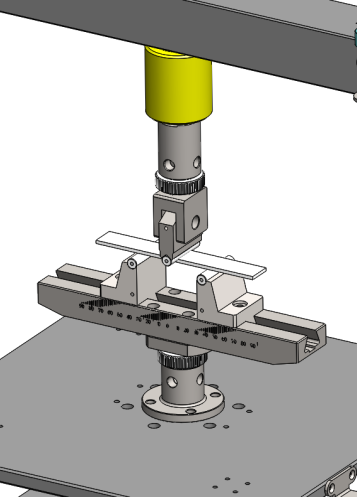

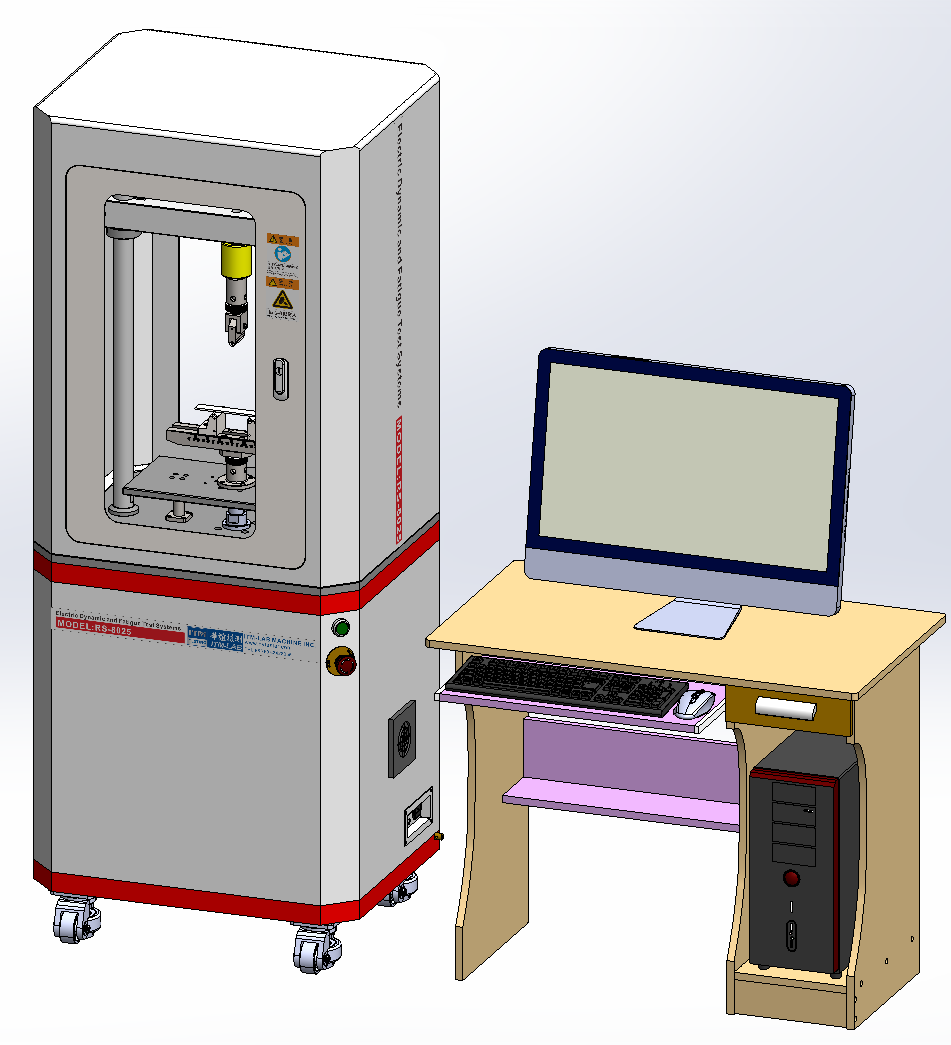

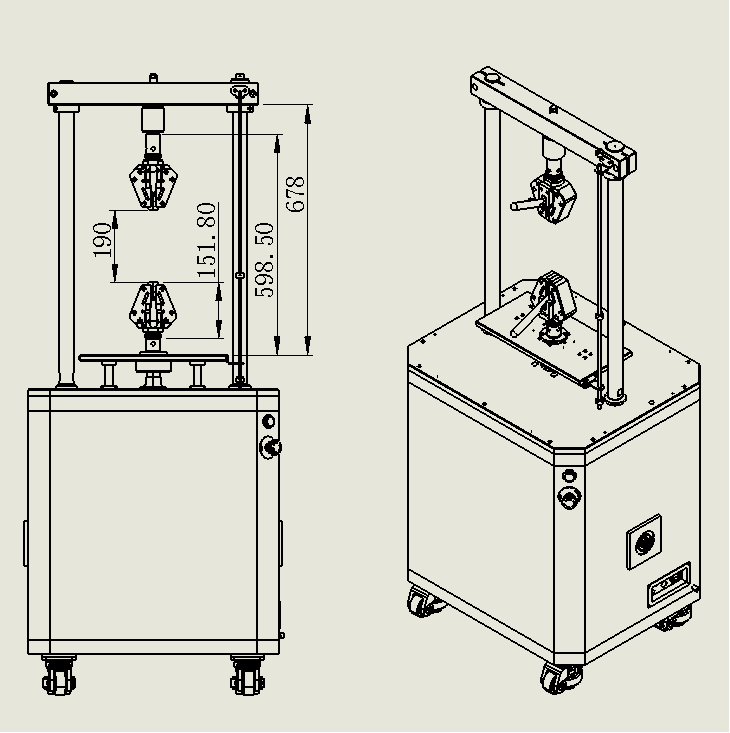

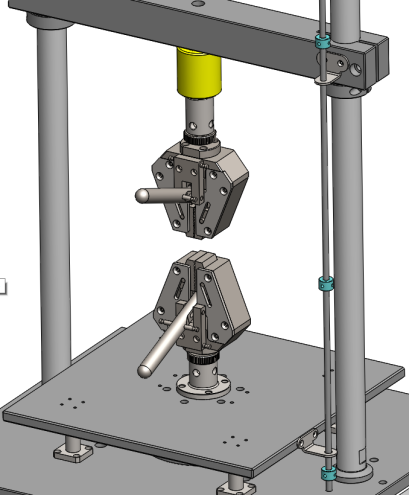

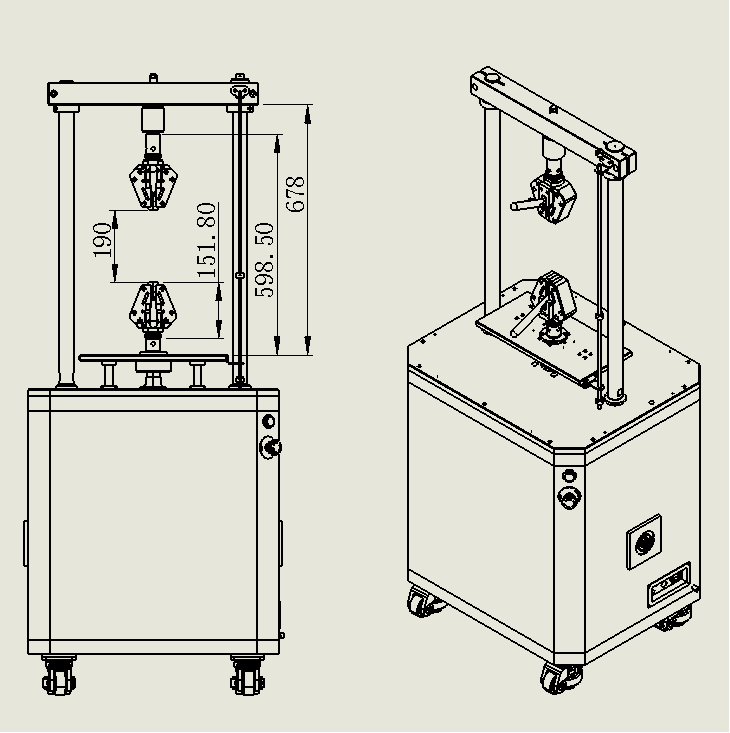

1, Main Unit: The closed-frame structure consists of two vertical columns, a base, and a crossbeam, providing high rigidity, no backlash, and good stability. The outer surface of the double columns is treated with electroplated hard chrome. The servo motor is positioned below and directly connected to the ball screw, ensuring zero backlash and better feedback.

2, Key Components: Uses internationally renowned brands --- Panasonic servo motors from Japan and high-precision load cells from the USA.

4, Control Method: Force, displacement, and deformation PID cyclic control, with smooth switching between any control modes.

5, Testing software: suitable for Windows 10 operating system. Capable of setting testing methods, managing storage methods, automatic storage of test data, printing test reports, and other functions.

6, Testing waveforms: sine wave, square wave, triangle wave, trapezoidal wave, ramp wave, sawtooth wave, user-defined waveforms, etc.

7, Protection functions: overload, motor overheating, preset fatigue count reached, specimen fracture, and other alarm shutdown functions.

Working conditions:

1, Ambient temperature: 15~30 ℃

2, Relative humidity: ≤ 85%

3, Power supply: AC 220V 50Hz, main line configuration must meet 1.5KVA power requirements.

4, The equipment must be installed on a solid, level ground, Levelness of the testing machine: 0.2/1000, Ground load capacity: 3 times the weight of the equipment

5, The equipment should be used in an environment free from vibration, corrosive media, and strong magnetic interference, with good ventilation

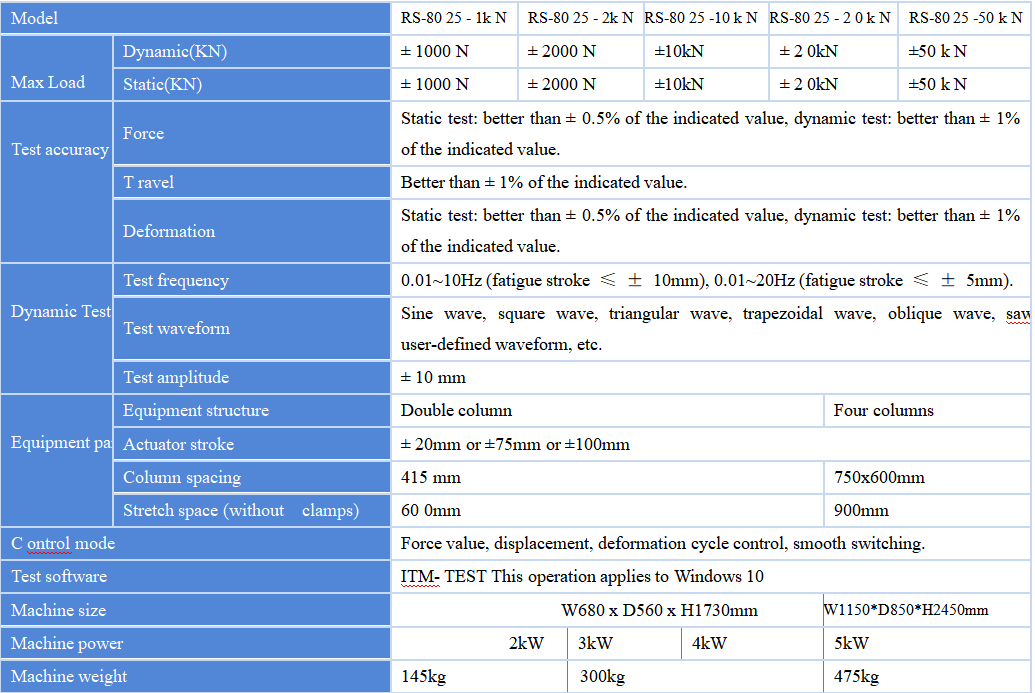

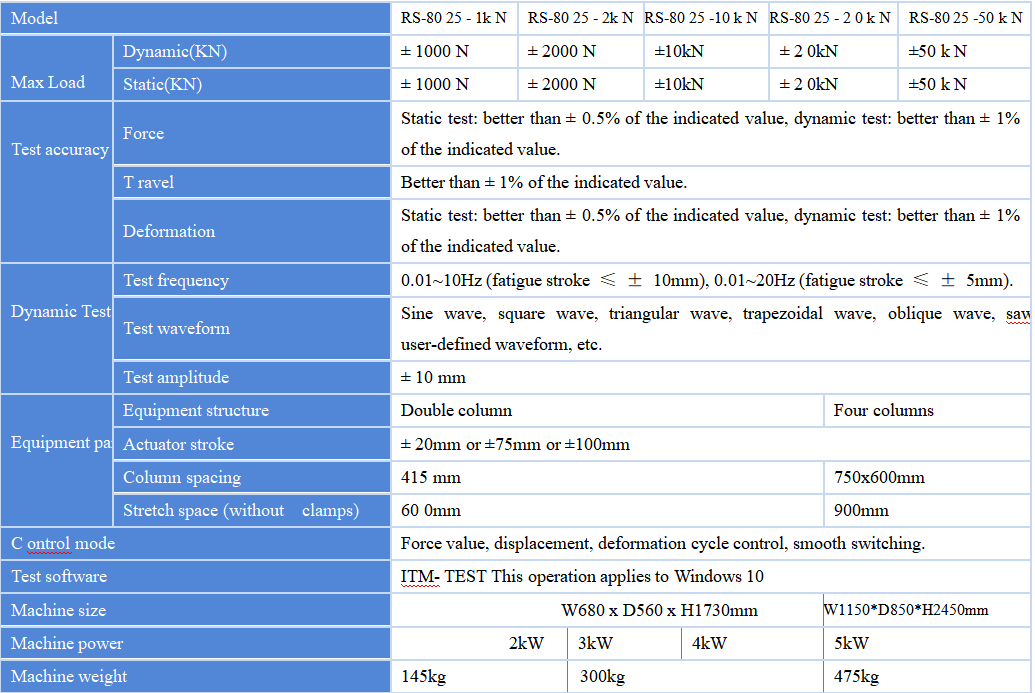

Technical parameter:

Test software:

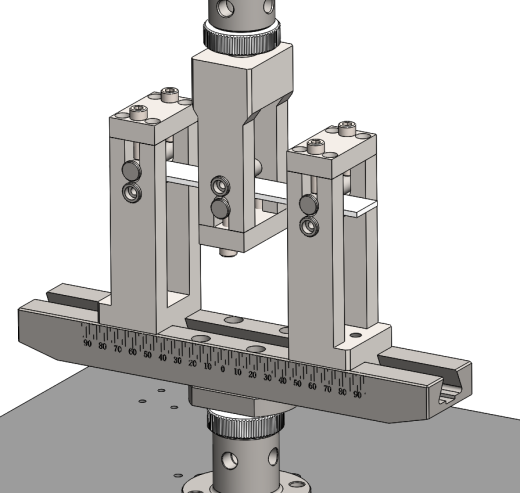

Optional:

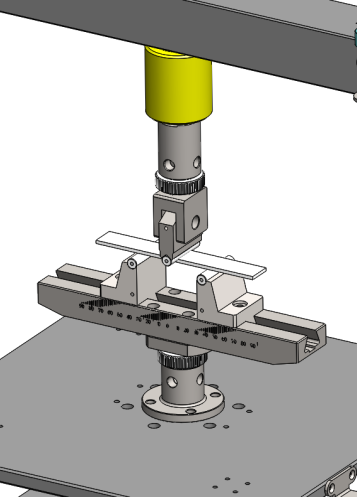

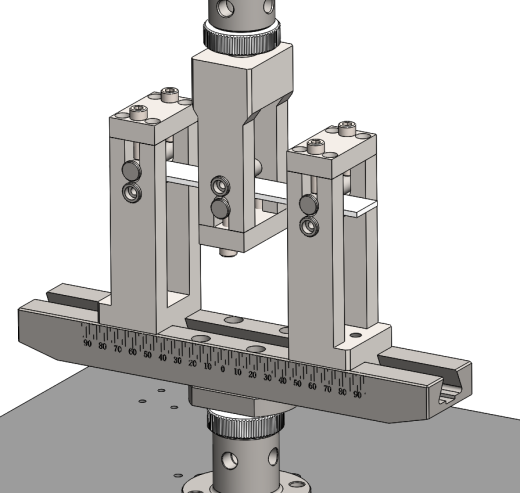

Three point bending fatigue ASTM D7774 fixture

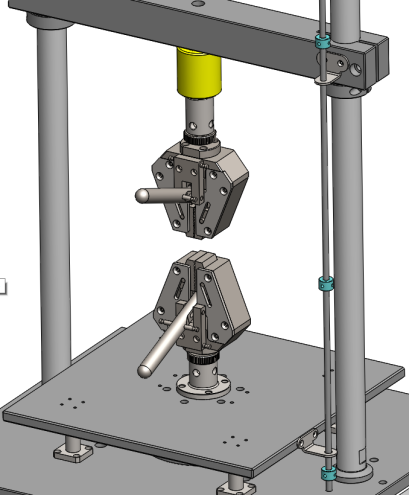

Standard drawing wedge fixture

Standard ASTM D790 three-point bending fixture

Equipment Introduction:

The dynamic fatigue testing machine is primarily used for testing the dynamic and static mechanical properties of various metallic materials, non-metallic materials, components, elastomers, rubber elasticity and dampers, composite materials, and lithium battery core poles. It can perform tensile, compression, bending, low-cycle and high-cycle fatigue, crack propagation, and fracture mechanics tests under sine wave, triangle wave, square wave, trapezoidal wave, ramp wave, sawtooth wave, and user-defined conditions.

The testing machine is easy to operate and flexible, utilizing AC servo motor drive technology for loading, high-precision load sensors, and high-resolution displacement sensors to measure the force and displacement of the specimen. It meets the requirements for dynamic fatigue testing of materials as well as static tensile and compressive tests.

The fully digital measurement and control system can achieve force, dynamic displacement, and deformation cycle control. During the testing process, it displays the test's force value, displacement value, dynamic load value, static load value, and the upper and lower peak values, frequency, cycle count, and test duration in a non-file digital format, while simultaneously tracking and displaying the force and displacement curves in real-time; it also allows for real-time display and capture of dynamic data and waveforms. Flexible data storage method, during the test, automatically save test data in real-time based on the number of cycles or test time, ensuring the safety of test data.

According to standards:

Complies with GB/T2611 'General Technical Requirements for Testing Machines', 'Electronic Universal Testing Machines' GB/T 16491-2008, 'General Technical Requirements for Testing Machines' GB2611-2007, 'Detection of Force Measurement Systems for Tensile and Compression Testing Machines', 'Technical Conditions for Extensometers' JB6146-2007, and 'General Specifications for the Licensing Assessment of Manufacturing Measuring Instruments' JJF1246-2010. GB/T3075 'Metal Axial Fatigue Test Methods', JB/T9379 'Technical Conditions for Tensile and Compression Fatigue Testing Machines', GB/T228 'Room Temperature Tensile Test Methods for Metallic Materials', and other standard requirements.

Performance Characteristics:

1, Main Unit: The closed-frame structure consists of two vertical columns, a base, and a crossbeam, providing high rigidity, no backlash, and good stability. The outer surface of the double columns is treated with electroplated hard chrome. The servo motor is positioned below and directly connected to the ball screw, ensuring zero backlash and better feedback.

2, Key Components: Uses internationally renowned brands --- Panasonic servo motors from Japan and high-precision load cells from the USA.

4, Control Method: Force, displacement, and deformation PID cyclic control, with smooth switching between any control modes.

5, Testing software: suitable for Windows 10 operating system. Capable of setting testing methods, managing storage methods, automatic storage of test data, printing test reports, and other functions.

6, Testing waveforms: sine wave, square wave, triangle wave, trapezoidal wave, ramp wave, sawtooth wave, user-defined waveforms, etc.

7, Protection functions: overload, motor overheating, preset fatigue count reached, specimen fracture, and other alarm shutdown functions.

Working conditions:

1, Ambient temperature: 15~30 ℃

2, Relative humidity: ≤ 85%

3, Power supply: AC 220V 50Hz, main line configuration must meet 1.5KVA power requirements.

4, The equipment must be installed on a solid, level ground, Levelness of the testing machine: 0.2/1000, Ground load capacity: 3 times the weight of the equipment

5, The equipment should be used in an environment free from vibration, corrosive media, and strong magnetic interference, with good ventilation

Technical parameter:

Test software:

Optional:

Three point bending fatigue ASTM D7774 fixture

Standard drawing wedge fixture

Standard ASTM D790 three-point bending fixture